Bourdon stands for more than 160 years of expertise in measuring technology, pressure measurement by what has become a classical solution – the Bourdon tube.

In 2005 the Bourdon Haenni company became part of the Baumer group and is now Baumer’s competence center for mechanical measuring instruments.

The Baumer group employs about 2,500 workers worldwide in 36 subsidiaries and 18 countries.

-

Pressure, Diff. Pressure gauges.

-

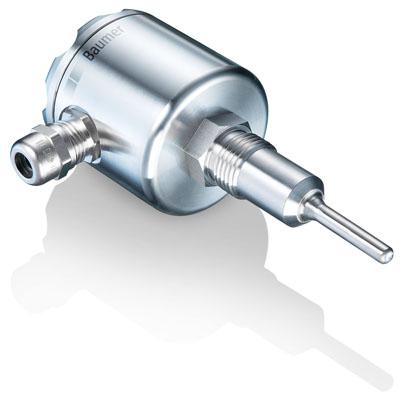

Pressure and temperature transmitters.

-

Temperature indicator.

-

Pressure and temperature switches.

-

Chemical seals and accessories.

-

Digital pressure, temperature gauges.

Bourdon provides various pressure measuring technologies on mechanical instruments.

Along with the Original Bourdon tube pressure gauge, we manufacture capsule sensing elements for low pressure application as well as diaphragm and bellow pressure gauges for specific process requirements.

Differential pressure gauges are designed to guarantee accurate reading of pressure differences between two points of your process. Typical applications are e.g. filter monitoring, hydrostatic tank level measurement in closed tanks and flow measurement.

•Durable, precise, and optimally adapted pressure sensors for every application.

•Pressure sensors, pressure transmitters, and pressure switches.

•Optimum technology for every application.

•Relative pressure, absolute pressure, and vacuum measurement.

•Wide portfolio of process connections and adapters.

•ATEX approvals for the Ex area.

•Fast commissioning, efficient processes thanks to IO-Link interface.

Temperature gauges are a good choice for local temperature reading close to the process. They are reliable, need no external power supply and allow constant process monitoring.

The pressure can be too high or too low. Pressure switches have no precise local indication, no analog output signal and need no electrical power supply. These simple devices are purely optimized to guarantee an excellent repeatability and reliability of the switching behavior.

Mechanical differential pressure switches have been developed to switch an electrical contact, when the difference between 2 pressure values in a process exceeds defined limits. The pressure difference can be too high or too low. Differential pressure switches have no precise local indication, no analog output signal and need no electrical power supply. These simple devices are purely optimized to guarantee an excellent repeatability and reliability of the switching behavior.

Protect pressure gauges and sensors in extreme process conditions and ensure hygienic requirements in food and pharmaceutical applications (Corrosive fluids, Fluids with high viscosity, Fluids that solidify at ambient temperature, Very high or low process temperature).

Installation accessories available together with the pressure gauges, Protecting the measuring instruments from harsh process conditions, Easy installation and isolating for maintenance and calibration.

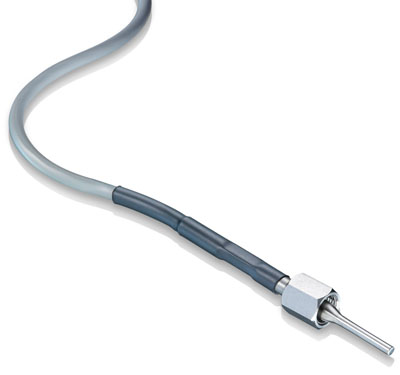

They enable customized solutions for almost any task in temperature measurement – absolutely precise and reliable.

Mechanical temperature switches have been developed to switch an electrical contact, when a temperature in a process exceeds defined limits. The temperature can be too high or too low. Temperature switches have no precise local indication, no analog output signal and need no electrical power supply.

The economic alternative for measuring the temperature of liquids or gases from -50° C to +205°C.

Our potentiometric level transmitters precisely measure homogeneous fluids.

Contact-free measurement of any materials - reliable from a few centimeters to a few meters.

Conductive filling level switches detect conductive fluids rapidly, reliably and to the millimeter.

CombiLyz® AFI4 features an integrated graphical LCD display with 3 different backlight colors. Conductivity (µS/cm or mS/cm), concentration (%), temperature (°C) and also the customer-specific medium name are conveniently indicated for on-site control. CombiLyz® AFI4 is quickly configured on the spot without a computer using the touch screen. Alternatively sensor programming is also feasible by FlexProgrammer.

Baumer conductive filling level switches detect conductive liquids quickly, reliably and to the millimeter at up to four switching points.

They are robust, extremely resistant and so are particularly ideal for filling level measurement and dry running protection for pumps. In a compact, hygiene rules compliant design with 3A certification, these are used around the world in the food and beverage processing industry.

The sensor we use can withstand temperatures from –20 to 140 °C and is therefore also suitable for CIP and SIP processes.

As the measuring rod can be shortened to any length needed, every installation becomes extremely simple.