SMAR is a Brazilian brand, created on April 1, 1974, controlled by the company Nova Smar S/A, based in the municipality of Sertãozinho, state of São Paulo, currently positioned as a Technology Company, specialized in providing solutions for the control and automation of industrial processes, attentive and closely following the rapid advance of digital technologies, which have caused the emergence of innovative, differentiated and even disruptive resources, many of them interesting, applicable and that can be associated with automation solutions.

SMAR develops, manufactures and sells instruments, controllers, hardware and software for measurement, control, operation and asset management. Provides Project, Factory Acceptance Test, Site Acceptance Test, Site Integration Test, Commissioning, Start-up and Technical Assistance services.

-

Pressure, Diff. Pressure, temperature, level and flow transmitters.

-

Remote seals, manifolds, Etc.

-

Universal Smart Valve positioners.

-

Density / concentration transmitters.

-

Hart configurators.

-

Fieldbus systems FCS.

-

DCS, PLC and hybrid controllers.

-

Pilot plant / training simulators.

• Accuracy ± 0.0004 g/cm³.

• Range 0.5 - 5 g/cm³; • Standard industrial and sanitary (3A) process connection.

• Multifunction rotary display LCD.

• Two-wire loop powered.

• Several different wetted materials.

• Single integrated unit, without moving parts.

• Factory calibration and self-calibration.

• In-field re-calibration.

• No standard reference required.

• No lab calibration required.

• No process shutdown.

• Continuous/self-diagnostics.

• Weather proof, explosion proof and intrinsically safe.

• Totally digital; including sensor, electronics and communication.

• Configurable via local adjustment (FOUNDATION™ fieldbus and PROFIBUS-PA).

• Easy firmware upgrade (via Flash Memory Interface) for FOUNDATION™ fieldbus and PROFIBUS-PA.

• Auto-tuning of the PID parameters.

• Partial Stroke test.

• Linear and rotary applications.

• Non-polarity power supply input.

• Travel: Linear Motion: 3 to 100 mm; Rotary Motion: 30° to 120°.

• Pressure Supply: 1.4 - 7 bar (20 - 100 psi).

• Flow Characterization: Linear, Equal Percentage, Quick Opening or configurable.

• Aluminum or 316 SST.

• Indicator with 4½ - numerical digits and 5-alphanumeric characters.

• Certifications for Hazardous Areas: explosion-proof and intrinsically safe.

• More than 100 types of configurable parameters for diagnostic of control valve.

• ± 0.75% accuracy.

• Wide range of pressures, up to 25 MPa (3600psi).

• Totally digital, including sensor, electronics and communication.

• Several options for process connections.

• Response time 100ms.

• Simple (zero and span) and complete local adjustment.

• MTBF (Mean Time Between Failures) of 239 years.

• 40:1 rangeability.

• Configuration and remote diagnostics by HI331 and FDT/DTM.

• Multifunction rotary display.

• Digital communication via HART®, FOUNDATION™ Fieldbus, and PROFIBUS PA protocols.

• Weather proof, explosion proof and intrinsically safe.

• Built-in transient suppression.

• ± 0.040% accuracy for L1 models (high performance).

• ± 0.2% of URL stability - Guarantee for 12 years.

• Wide range of pressures, up to 40 MPa (5800 psi).

• 120:1 rangeability.

• 100 ms total response time.

• PID control capability.

• Advanced diagnostics.

• Bi-directional flow measurement.

• Support for DD, EDDL and FDT/DTM.

• Built-in transient suppression.

• Low Total Probable Error.

• Multifunction rotary display.

• Simple (zero and span) and complete local adjustment.

• Weather proof, explosion proof and intrinsically safe.

• ± 0.045% accuracy.

• 200:1 rangeability.

• 35 ms total response time.

• Non-polarity power supply input.

• HART® Protocol.

• Suitable for installations requiring SIL2 and SIL3.

• ± 0.045% accuracy.

• ± 0.2% of URL Stability - Guarantee for 12 years.

• 200:1 rangeability.

• Advanced diagnostics.

• Support for DD, EDDL and FDT/DTM.

• Local adjustment: simple (zero and span calibration) and complete.

• Low Total Probable Error.

• Repeater/router function in mesh network.

• “Burst Mode” for sending periodics statements.

• Battery operation for long duration.

• WirelessHART™ Protocol.

• ± 0.2% accuracy.

• 4-20 mA output signal according to NAMUR NE43.

• HART® and PROFIBUS-PA Communication Protocols.

• Several Process Connections Options.

• Cabe Gland Electrical Connection - Without Polarity.

• Wide range of pressures, up to 150 bar.

• 50:1 Rangeability; • Operation Temperature: - 40 to 85 °C.

• Response time 200 ms.

• Zero and Span Local Adjustment.

• Configuration Protection with Password.

• Housing Material in 17-4PH / AISI316L.

• Diaphragm Material in Hastelloy C276.

• Fill fluid in Silicone.

• Support for DD, EDDL and FDT/DTM.

• IP65 rated enclosure.

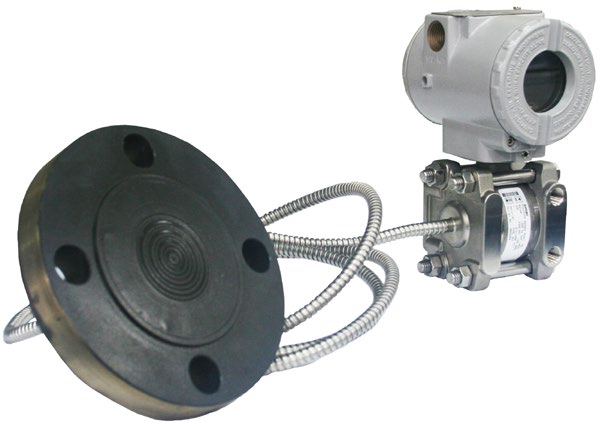

• The SR301 series is a complete Remote Seal line, which is coupled on the pressure transmitters to meet different applications such as very high or very low temperatures, areas of difficult access or with too much vibration.

• SR301T: Flanged remote seal for general applications. The flush connection is optional.

• SR301E: Flanged remote seal with extension for general applications and it is very used when the tank wall is coated.

• SR301P: Pancake type remote seal especially used in applications with limited installation area. It may be supplied optionally with flush connection.

• SR301Q: Pancake remote seal with extension.

• SR301R: Threaded remote seal for general applications with a wide variety of threaded connections. Optionally it may be supplied with flush connection.

• SR301S: Sanitary remote seal especially designed for use in food industries and other applications where sanitary connections are required.

• ± 0.02% accuracy.

• Built-in thermocouples and RTD’s linearization;

• True non-interactive zero and span.

• Remote configuration via Hand-Held Terminal or PC.

• Small and lightweight.

• Explosion proof and weather proof housing.

• EMC (Electromagnetic Compatibility) according to IEC standards.

• Write protection function.

• Intrinsically safe.

• Three technology options: HART®, FOUNDATION™ fieldbus, and PROFIBUS PA.

• Support for DD/EDDL and FDT/DTM.