Since the release of the first positive displacement flowmeters to Japan market in 1949, OVAL has been developing and producing wide range of flowmeters, related products and system products.

Applications of these products have been extended to variou processes in the industries and the products earned high reliability from customers. Utilizing accumulated know-how as valuable.

-

Positive displacement flowmeters.

-

Coriolis flowmeters.

-

Vortex flowmeters.

-

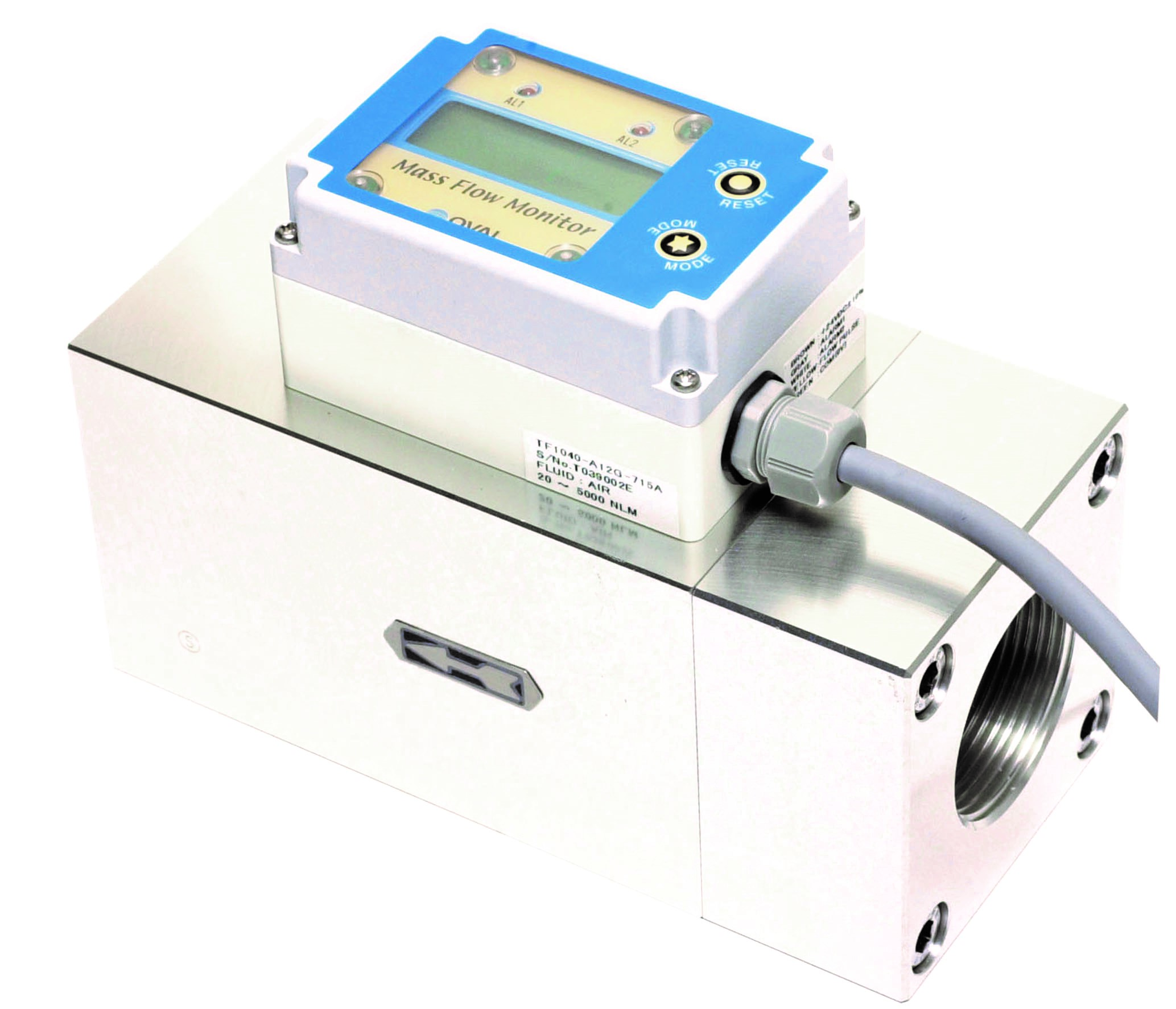

Thermal mass flowmeters.

-

Turbine flowmeters.

-

Meter provers.

Bar graph display enables intuitive confirmation of instantaneous flowrate.

-Easily viewable, large unit display.

-Highly sensitive touch sensor has been introduced! Operable with your gloves on, even in the rain.

-Predicts aging deterioration of the flowmeter body and notifies the maintenance timing.

-Detects disconnection of sensor wire and notifies sensor failure.

-Zero-point adjustment function (2 methods: Status input by front key operations or adjustment button on the transmitter).

-Error logging function.

-Clock function (Accmlated time from power on is saved in the transmitter).

-Factory default parameter reloading function.

-Parameter backup function to the display unit.

-Materialization of 2 wires transmission system for cost reduction and simplification of a system to be applied.

-Ease to data setting.

-Maintenance cost saving means increase of security operation.

-Maintenance operation such as range and parameter setting, and calibration can be performed.

The ultrasonic flowmeter measures the time of ultrasonic wave transmitted from one sensor and received by the other. This time duration is called "propagation time."

When there is no flow, the propagation time from sensor A to sensor B (Tab) and the propagation time from sensor B to sensor A (Tba) should be the same. However, once the fluid is flowing, ultrasonic signal is affected by the flow, creating a difference between propagation times Tab and Tba. The ultrasonic flowmeter measures propagation times Tab and Tba, then calculates the flow velocity from the difference in propagation times, and provides the flow rate by multiplying the flow velocity by the cross-section area of the pipe.loss of pressure.

A turbine flowmeter for industry application that allows stable high accuracy measurement for the liquid with a wide range of viscosity including low Reynolds number area. It is suited mainly for petroleum, liquefied gas, and water flowrates.

-A high degree of accuracy. Linearity to ±0.15% in the most demanding application.

-Low pressure drop saves energy.

-High resolution and consistent accuracy over many years' service.

-The turbine rotor made up with the latest precision-machining techniques features interchangeability.

-Fine ceramics and tungsten-carbide alloy are used for rotor bearings to increase durability.

-A broad operating range from −200℃ to +300℃.

-Boasts an exceptionally wide flow range〔10 to 600 (15mm), 135 to 8000 (50mm) L/min (normal)〕and range ability “1:60”no other meter can match. Accurate detection capability that extends to extremely low flowrates makes it ideal, not only to measure air consumption but also to locate air leaking spot.

-Thanks to the thermal dispersion principle of operation to detect mass flow, it requires no corrections for temperature and pressure. It directly indicates flowrate under normal operating conditions (at 0℃, 1 atm), which means most cost effective.

-Besides “total”,“ cumulative total ”and“ instantaneous flowrate (an hour every share)”, the display shows“Yen equivalent”an ideal for utility flowrate from an energy saving point of view.

-The sensor element is durable to dust, mist, etc. because it is protected by stainless sheathed pipe.

-Simple construction contributes to easy maintenance.

-Low pressure loss.

-Robust and durable.

-Compatible with other OVAL flowmeters, including DELTA flow meters (vortex meters), EX Turbine (turbine meters), and orifice meters.

-Designed to be sandwiched between flanges for simplicity of installation.