In May 1992, Claudio Bonello and Franco Masenello, driven by the experience they acquired as colleagues in the sales of industrial devices and by their will to start a their own activity, founded B.M.

Tecnologie Industriali. At the beginning it was founded as a representing and distribution company of industrial devices. The choice of rying to understand and satisfy our customers’ needs was the best solution we could find to make customers who were used to act out of habit, listen to us.

-

Ultrasonic flowmeter (fixed, portable).

-

Ultrasonic thickness gauge.

-

Level transmitters “ultrasonic radar”.

-

Leakage detection system.

-

Scada and telemetry solutions.

-

Wireless communication.

-

Electromagnetic flowmeter.

- High accuracy.

- Wide measuring range: from DN15 to DN6000, with 3 different types of clamp-on sensors.

- Clamp-on sensors for high temperature applications and insertion sensors for pipes up to DN2000.

- PT100 input for calory/BTU measurement.

-Flow measurement in full pipes and open channels

-TTFM KAPTOR: Ultrasonic Technology

-OCM KAPTOR: Doppler Technology

-Protection IP68

-Battery life: up to 1 year, expandable.

-Compact and easy to install.

-Digital and analog inputs for external sensors.

-Data acquisition on internal memory and SD Card.

-Data transmission to a remote system via GPRS.

-Software “HydroFlux” for data management and configuration.

-Suitable to work on our hydraulic software: Waterguard for menagement of Water Losses in Acqueduct and Channelguard for study of sewerage.

This new series follows the successful tradition of MUT 2200/2500 introducing a measurement range of more than 1:1000 without linearization software. These kind of performances allow very accurate measures on a wide flow rates, that, before, would have been reset because of the effects of the converters cut off.

The product’s compact size allows installation on small pipes, providing water monitoring in applications considered impossible

-Level measurement.

-flow measurement in open channels. Flow measurement on rectangular.

-pump control function based on level or running time of the pump. Duty assist or duty backup functions fixed or alternative.

Measuring Range (Metric / Imperial) 1.2-225mm / 0.05-9 Inch.

Measured Materials Any hard materials including steel, cast iron, red copper, brass, zinc, polyethylene, PVC, and other materials.

Sound Speed 500-9000 mt/sec.

Accuracy +/- (0.5% n + 0.1) – Calibration block included.

-Ultra Compact Ultrasonic.

-Level & Flow transmitters.

-New Generation.

-Range4-8-15 mt.

-Output 4…20 mA Hart.

For measure the fill level and control the level, for pump control, flow rates in open channels and overflow volumes on stormwater. Universal use for almost all liquids bulk solids without being in contact with the liquid. Measurement of level, distance, volume, difference and flow. High measurement reliability through integratedagitator avoidance. Esy echo analysis and setting of parameters via PC. Up to 6 relays and galvanically isolated mA output. easy oparation in dialog mode using back-lit graphic display. Integrated emergency power switchover

MicroLog Quite small datalogger very easy to use and to program. Equipped with 2 analogue input, 4 digital input and 2 relays. I/O expandible via RS485.

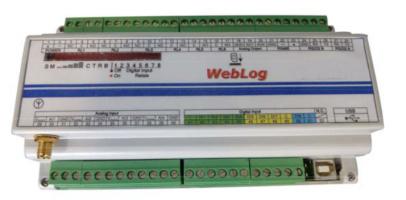

WebLog combine the functionalities of an RTU, a datalogger and a telemetry systems. Equipped with 8 digital input, 4 analog input 6 relays and 3 serial porta for connection with other electronic systems

WebCommander is a pump station management system built on the WebLog hardware. It includes therefore datalogging, programmability and GSM/GPRS communications.