Over 20 years of experience in the flow computer manufacturing and design.

Dynamic Flow Computers has over 20 years of experience in flow computer manufacturing and design.

We found our competitive advantage by designing innovative flow indicators to fulfill the needs of the oil and gas markets. Our responsiveness to the market’s needs is unmatched. Our flow computers are simple to use, but are able to perform the most complicated of jobs. The accuracy and reliability of our flow meters in custody transfer and measurement is always set to the industry standards.

-

Flow computer.

-

With built in multivariable transmitter,V-cone flow element.

-

V-cone element “smart cone”.

-

Turbine diagnostic.

-

Portable or stationary prover.

-

API, AGA, ISO compliance.

-

Optional wireless-solar power supply.

-

Metering skids, wireless transmitters.

The Micro MV is a 32-Bit, Dual Meter Run, custody flow computer for liquid, industrial gas, and natural gas applications featuring: three frequency channels, four analog inputs, one analog output, four digital I/O’s, one RS-232 port, two RS-485 ports, one printer output, and a rosemount multivariable transmitter. An input OR output expansion module is also available.

The E-Chart is a single meter run, custody flow computer for liquid or gas application featuring: one digital/status/frequency input, two digital/switch outputs, one analog output, and one RS-232/RS-485 communication port (2nd port is available with a WDS upgrade).

-The SFC 332N is a 32-bit bi-directional, dual meter run, custody flow computer used in liquid custody pipeline applications.

-Fifty (50) previous days, batches, and hours of historical data are stored in full format-type reports, as well as 100 previous audit trail reports and alarms. Sixteen (16) different product files are user-configurable with easy switch feature, and product scheduling for batch operation is available.

-Proving with automatic meter factor implementation is possible using uni-directional, bi-directional, reduced volume, Calibron ™ or Brooks™ type Provers. Automatic 4-way Valve / Piston Control is a standard proving feature. Repeatability is checked regularly by the flow computer.

-Special real-time turbine diagnostic functions are available to detect bent or missing turbine blades, wobble, pulsation or flow cavitation. A turbine meter signature is generated at different flow rates, and then assessed for changes in fidelity continuously. A frequency or analog signal can be received from a Densitometer.

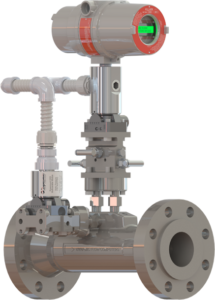

-An optional multivariable module 205 sensor may be integrally mounted to the SFC 332N to allow accurate determination of differential pressure, static pressure, and temperature.

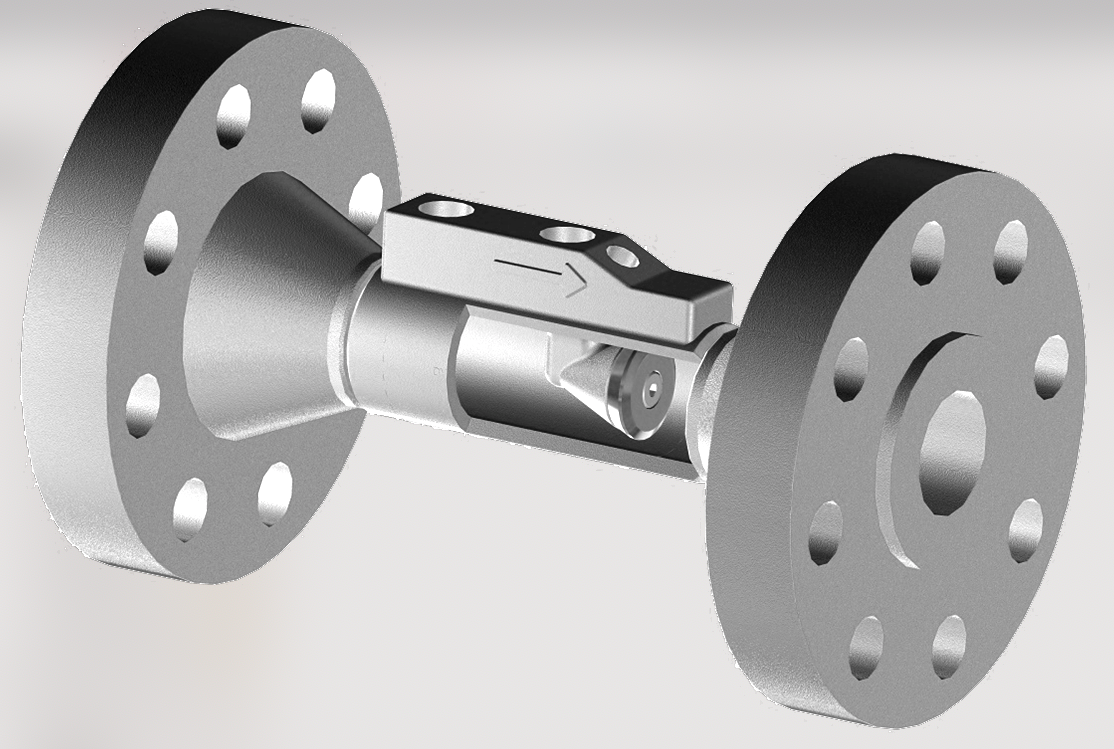

-The SmartCone™, a variable area/beta ratio differential pressure cone meter, is a fluid flow meter that uses a measured differential pressure to provide a robust, accurate, repeatable and optimal cost measurement solution for both gas and liquid measurement.

-The SmartCone™ meter produces a differential pressure which can be read by any standard differential pressure or multivariable transmitter.

-The meter is the first differential pressure cone meter to use artifact calibration techniques similar to orifice plate technology, which is inherent in the design. Each SmartCone™ meter has a verifiable geometry between subsequent manufactured devices using accurate and robust machined castings. It features the unique ability to offer a beta or area ratio change per diameter using interchangeable ARC’s. This allows the metered products’ flow velocity characteristics to be aligned correctly throughout the life of the meter.

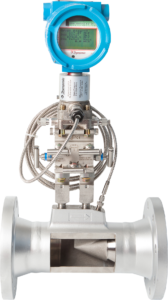

-FloCell is an integrated mass measurement solution which offers unmatched accuracy in its class. Unit installation and start-up have never been easier.

-Integrated Measurement Solution.

-Factory Pre-Configured for Application.

-25:1 Total Turndown.

-Better than 0.1% accuracy.

-Easy Installation and Start-up.

DynaCone X is a fully integrated flowmeter. It maintains a database of all fluid and setup parameters and reports real-time flow rates at line and standard conditions both on the Flow Computer or digitally over Modbus®. No additional external equipment is required for operation. The compact, in-line design is minimally intrusive with low pressure drop and no scheduled maintenance requirements. The low power consumption and high ambient temperature rating make it suitable for solar panel power and desert applications. It is designed for Class 1, Division 1 hazardous locations.

▪Non-nuclear. ▪ Two independent primary instruments: Cone and Pitot Tube. ▪ Large turndown ratio (30:1). ▪ Self-Aligning/Self-Centering SmartCone®. ▪ Cost efficient solution. ▪ No upstream/downstream straight length requirements. ▪ Area/Beta Ratio Changer.